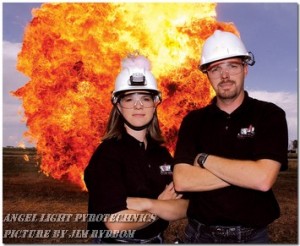

In a bang-up Zoom presentation on May 19, Larry and Ginger Darringrton of Angel Light Pyrotechnics, LLC, introduced us to the intricacies and joys of the pyrotechnic (read fireworks) business. By way of introduction, Larry assured us that they are pyrotechnicians, not pyromaniacs.

In a bang-up Zoom presentation on May 19, Larry and Ginger Darringrton of Angel Light Pyrotechnics, LLC, introduced us to the intricacies and joys of the pyrotechnic (read fireworks) business. By way of introduction, Larry assured us that they are pyrotechnicians, not pyromaniacs. Larry and Ginger's presentation came from their special storage facility that meets all of the ATF (Alcohol, Tobacco, Firearms) regulations. Their company, the culmination of three generations of interest in fireworks, is the biggest (and arguably the best) pyrotechnics company in Colorado. They are a service company (no retail sales) that designs, sets up, executes, and cleans up fireworks shows over much of Colorado.

In talking about how the company works, they stated that they have only one employee; most of the actual physical work is done by volunteers (in fact, the chief way to get into the industry is to volunteer at a company like theirs). It takes a lot of work to set up a show and that would be too expensive to be done by employees. As a result, a significant part of what they do is to provide a two-day company training course, concentrating on both regulations and procedures, in order to build confidence, safety, and efficiency into their operation. In October, they will start to offer a course for the general public, for example volunteer fire departments and other organizations that may only do fireworks shows once each year. Walking away from a show with all fingers and toes intact is a good result. In the history of their company, the only injuries have been some minor cuts; no injuries of any kind associated with explosions or fires.

The actual mechanics of creating fireworks is a combination of 2000-year-old chemistry with modern technology. The original fireworks created by the Chinese consisted of black powder in lengths of bamboo. Modern technology allows similar combinations to be timed to the nearest 1/1000th of a second. But the staple remains black powder in the tube (to get the shell into the sky), the fuse (to make everything blow up at a safe distance), and the shell (which explodes to make the visible display. The actual shell is a sphere of paper mache which includes two fuses (for redundancy) and a collection of black marbles made up of gunpowder with an admixture of fine metal to provide the colors. The fuse burns at 150 feet per second and is ignited electrically using an electric match that allows for high accuracy of timing. All of this electronic control has come in since 1990 and, along with “Fire Flix” software, allows choreography of the firework display with a music sound track or even movies. And the combination of electronic control with quality control of the explosive product allows the creation of shows that can be done outdoors or indoors, night time or day time.

Angel Light is licensed to manufacture pyrotechnics in Colorado, but most of the material is imported from China. One of their biggest challenges is over-regulation. They are subject to a whole alphabet of government agencies, commonly with overlapping areas of responsibility and occasionally with conflicting regulations. As a result, there is a high barrier to entry to the field due to the abundance of recent regulations and more fireworks companies are leaving Colorado than are starting. The entire operation is labor intensive because most of their processes are very difficult to automate. The payoff is that they get to blow things up, get paid, and do it as a family with thousands of people cheering (occasionally more people than attend a Bronco’s game). Commonly the cheering of the crowd is augmented by the blaring of car alarms set off by the explosive shocks.

As a result of an issue that arose in firing off a fireworks tribute to Larry’s recently deceased father, they were peripherally involved in the largest fireworks shell ever shot, a 62” diameter (that’s five feet!), 2700 pound shell that was fired at a show in Steamboat. Although Angel Light was not directly involved in the Steamboat show, a damaged piece from the show for Larry’s father was necessary for the safe deployment of the giant shell.

In response to several questions:

There is really only one company in the world, Lloyds of London, that provides insurance for these sorts of operations. This is their second largest overhead expense, providing a minimum of $1 million coverage with an aggregate total of $2 million or more. They work hard to exceed the insurance company’s requirements to avoid any issues.

Although there is no “shoot by” date, the shelf life of the materials is determined by heat and humidity so Colorado is an excellent place for long shelf life.

In testing their explosives on their relatively large industrial site, they always warn their neighbors, including telling 911 what is coming. Commonly the neighbors come out to watch.

The most difficult colors to create are blue followed by purple. Those colors are difficult to see through the smoke of the explosions. They require very pure ingredients.

They create ground fires almost all the time, but only rarely big ones. The entire team is trained in ground-fire suppression.

They insist on complete personal protective equipment (PPE) for their crews, so they minimize the risk of, for example, hearing impairment.

There doesn’t seem to be any technology on the horizon that could effectively replace explosive fireworks. Occasionally drones or lasers may be used in conjunction with fireworks, but alone they are, at best, underwhelming.

Both lightening and wind can provide serious threats. All of their electrical equipment, including the electric matches, are shunted to protect against fugitive currents. Since the shows are pre-loaded (loaded on site ahead of time), there is always the possibility of some accidental wrong timing, but their procedures have kept that from happening. Wind is a problem in that it can cause drift of embers.